UltiMaker has heard the prayers of 3d printing nerds everywhere with the launch of the new Ultimaker S7. It's been 5 years since the release of the award-winning S5, packed with a handful of features, such as the adaptive bed levelling, filament flow censoring, and the ability for metal 3D printing.

This time around, what can we expect from the S7? Why should you buy it even when you already have the S5? To convince you, here are the 5 reasons to buy the new Ultimaker S7.

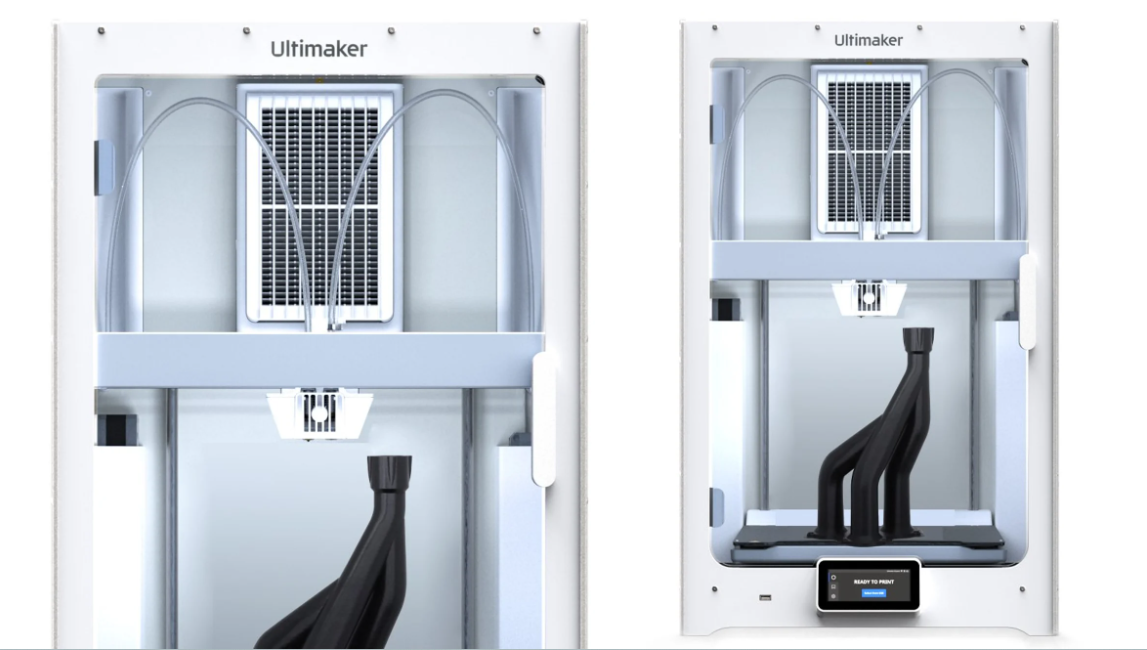

1. Built-in air control and filtering

The Air Manager is designed to “remove fine particles from every 3D print by up to 95%.” Since the build chamber is fully enclosed, it will also improve print quality.

2. Easier print removal

One of the most frustrating things about 3D printing is seeing your 3D printing project come to life only to hit a snag upon removing the print from the bed. That will never be the case with the Ultimaker S7 with its flexible build plate.

The S5 had a glass build plate that sometimes made it hard to remove 3D prints. It was also prone to breaking.

The flexible build plate is also covered with a new proprietary PEI coating to prevent warping and peeling at the corners. It also strengthens the release and adhesion, eliminating the need for bed adhesives.

3. Impeccable intuitive bed levelling

It’s easy to get a perfectly levelled bed with the Ultimaker S7’s inductive print head sensor. It offers a smart automatic bed levelling by probing the build plate with more accuracy and less electrical noise to allow for micron tolerance measurements.

This new inductive print head sensor is an updated version with a brand-new algorithm. This new algorithm enables “live bed tilt compensation,” a feature that prints the part perfectly aligned to the measured bed.

Aside from improving the bed levelling, the print head is also equipped with a sensor that stops the printing and warns the user if a 3D print has become the dreaded spaghetti.

4. Improved temperature control

The Ultimaker S7 is equipped with two state-of-the-art components that deliver exceptional temperature control.

One, the new build plate assembly improves the temperature throughout the build chamber. It is made with a 5-mm thick aluminium spreader with embedded magnets that secures the flexible build plate and evenly distributes the heat. Not only does S7’s flexible build plate make it easy to remove prints, but it is also designed to spread the heat better around the build surface to provide a more consistent adhesion temperature.

Two, the Ultimaker S7 only has a single door now to make it more airtight and prevent cool air from entering the build chamber versus S5’s double doors. While air can’t be completely eliminated within the chamber, any air that comes in around the gaps of the door is heated by the build plate passively and then travels through the printer chamber.

5. High-resolution camera and better view of the printing chamber

One problem that many users had with the S5 was the low-resolution camera in the internal chamber monitor. The S7 is now equipped with a higher-quality camera and a better viewpoint of the build plate for easier remote monitoring.