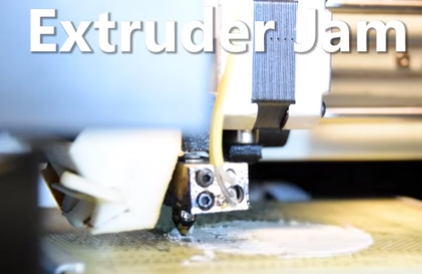

You feed the filament into the mouth of the extruder but it won’t push through. Or it could be that it can only push past partially but suddenly got stuck halfway through. Either way, you have a problem on your hands and forcing the feed of filament to push through can ruin your print.

Solutions:

It could be caused by a confluence of factors, including issues with the extruder motor or Bowden tube, loose motor cable or, extruder blocker.

-

Check if your extruder motor is clicking:

- If your extruder motor is emitting clicking sounds, the first thing you should do is look if your filament is deformed. If it has been flattened to become wider than it usually is, reduce the idler pressure on the feeder gear. On the other hand, you should increase the idler pressure if the filament has a gouge taken out of it.

- Second, decrease the strain by reducing the number of retractions or make the retracts less aggressive.

- Third, inspect the PTFE liner and make sure that it is not worn out or degraded by turning up the heat too high at 260°C. It could also lead to clogs and leaks if it has been frayed or cut. This will cause the liner’s diameter to become smaller.

- Fourth, the nozzle could be clogged. You can use our comprehensive guide to unclogging 3D printer extruder nozzle here.

-

Inspect the Bowden tube: If your printer uses a Bowden extruder, check for the following:

- Debris inside the tube

- Worn out areas with increased friction on the inside

- Too high bend radius

- Frayed or cut tube

- Pushed into the hotend

-

Probe into the feeder part of the extruder:

- It could be that the filament has been eaten away by the feeder gear. Clean this section.

- You should also adjust the idler pressure spring as it could be that the idler is not applying sufficient pressure to push the filament out.

- When the teeth of the feeder gear are worn, it could also cut your continuous flow of filament. These teeth should also be cleaned from time to time as they accrue debris.

- Ensure that the thermister is working as it may turn off sometimes due to the firmware settings.

- Check out if the motor is working okay: If anything goes wrong with the motor (loose or broken cable, failed motor, loose connector pin, etc.), stop the printing immediately and turn your machine off.